PORON

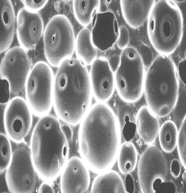

PORON was introduced through a technical partnership between Inoac and the Rogers Corporation, USA. PORON permits a wide range of design solutions for sealing and energy absorption.

PORON® has very low compression set

2. High Sealability

PORON® provides high sealing performance

3. Thickness Accuracy

PORON offers outstanding thickness accuracy

4. No Migration

PORON has minimal migration effect on other materials

5. High Fabricating Efficiency

PORON® is a material with high fabricating efficiency

6. High Dimensional Stability

PORON® provides excellent dimensional stability

7. Excellent Energy Absorption

PORON® offers excellent impact absorption

| Special blending technology | Integral molding technology | Special surface technology |

|---|---|---|

| Flame-retardant ・ Waterproof ・ Flexible ・ Antistatic | Thin layers ・ Adhesives | Patterns ・ Coatings ( High friction ・ High slidability) |

| Thickness | Minimum | 0.15mm |

| Maximum | 15.0mm | |

| Tolerance | Regular Products (thickness 0.6mm and up) | Within ± 10% |

| Thin products (thickness up to 0.5mm) | ±0.05mm | |

| Width | General Products | 500mm |

| Special Products | Up to 1000mm (Differs by grade so please contact us) | |

| Delivery Form | Roll products | Length (Please check the number of lots in the product availability on the right chart) |

| Sheet products | 1M units (Please check the number of lots in the product availability on the right chart) | |

| Roll Length | Thickness up to 0.5mm | 100M |

| Thickness between 0.6mm – 3.0mm | 50M (3.0mm thickness has cases of 40M by grade.) | |

| Thickness 4.0mm and up | 1M – 40M (Please check the product availabilty on the right chart.) |

With variety of density lineup, this series corresponds various applications, such as seals, vibration insulation and shock absorption

PET support series

PET film body molding technology realizes a thinner foam with a low resilience and contains additional features, such as flame-retardant properties. This series can satisfy any field of customer needs

This series features low-gassing and flame-retardant (UL94 HBF) with consideration to safety and environmental protection

SPECIAL SURFACE series

While maintaining the same basic characteristics, we have added a series with new features like high friction and high slidability, through special surface treatment

Standard Series

Low compression set, high sealability, excellent energy absorption, no migration, high dimensional stability, high fabricating efficiency, thickness accuracy

With variety of density lineup, this series corresponds various application, such as seals, vibration insulation and shock absorption

| LE | The softest product in the standard series. With its low stress property and compressibility; this type has been widely used for toner seals. |

| L | A softer product in the standard series being used for a wide range of cushioning and packing materials. |

| H | A hard product in the standard series. This type offers a high physical strength being used as sealing materials or vibration damping materials. |

| HH | A harder product primarily being used for the foot pads of audio devices; home electric appliances and office appliances. The C type that has excellent gripping property is also available. |

LO/RF Series

Flame-retardant, low out-gassing, low compression set, high sealability, excellent energy absorption, no migration, high dimensional stability, high fabricating efficiency, thickness accuracy

This series features low out-gassing and flame-retardant (UL94 HBF) with consideration to safety and environmental protection.

| MS | A product similar to the LE type in the standard series. It is one of the softest materials among the LO/FR series allowing for production of very thin products |

| ML | A soft material similar to the L type in the standard series. |

| MH | A hard material similar to the H type in the standard series. |

| CH | A hard material which is similar to the H type in the standard series. Additionally EG type (special surface treatment ) is also available |

| TR | This highly heat-resistant type achieves overwhelmingly low compression set at a high temperature range (70ºC – 110ºC). Even at room temperature; it delivers more stable performance. |

PET Support Series

Thinness, soft, rigid, low compression set, high sealability, excellent energy absorption, no migration, high dimensional stability, high fabricating efficiency, thickness accuracy

PET film body molding technology realizes a thinner foam with a low resilience and contains additional features, such as flame-retardant properties. This series can satisfy any field of customer needs.

| SR-S | The SR grade with low resistance is formed by casting low-resistance SR onto a PET film. Combining softness and strength; it has a great track record for products like smartphones; packaging LCE displays for PCs; and etc. A PN – type with adhesive is also available. (SR-S-15PN) |

| SR-N and SR-U | Flame-retardant materials and are UL94 HBF-certified. |

| ASRS | It has all the same excellent advantages as SR-S. Additionally ASRS is resistant to static electricity. It is ideal for anti-static applications. |

| SS | The high- resistance material; while similar to the Standard Series; is equivalent in softness to the SR-S grade. Its features excellent temperature dependence |

| WP | With our own unique formulation technology; this grade increased water-repellent performance This waterproof type passes IPX7 equivalent test. |

| MS;MH | This version of MS/MH is formed by casting LO/FR Series MS/MH onto a PET film. This is the PET Support Series’s high flame-retardant material. A PR-type with removable PET film is also available. (MS-40PR) |

Special Surface Series

Low compression set, high sealability, excellent energy absorption, no migration, high dimensional stability, high fabricating efficiency, thickness accuracy

While maintaining the same basic characteristics, we have added a series with new features like high friction and high slidability, through special surface treatment

| EG | The special surface treatment of this material provides not only less stickiness but a more stable and higher gripping force |

| CH-32EG | CH-48EG | MX-40EG | MX-48EG | |

| HF | This boasts the highest gripping force in the product lineup through special surface treatment technology |

| MX-48HF | |

| C | This exhibits a stable and higher gripping force though special surface treatment technology |

| HH-48C | |

| PN | A thin adhesive mechanism has been integrated into the casting process which provides a high adhesive force after the release liner is removed and eliminates the need for adhesive tape |

| SR-S-15PN | |

| PR | A thin adhesive mechanism is integrated into the casting process which provides a light adhesive force after the PET film is removed. It can be used as a temporary fixing or setting point in a repetitive process and it improves workability |

| MS-40PR | |

| T | The surface combines strong surface characteristics and excellent flexibility through special surface treatment technology |

| MS-40T | |

| LF | Special surface treatment technology provides higher surface slidability and adhesion prevention performance. |

| LE-20LF |